Looking for a Manufacturer with Turn Key Capabilities,

we are your source.

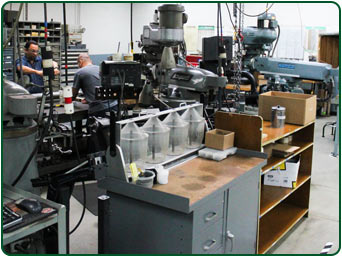

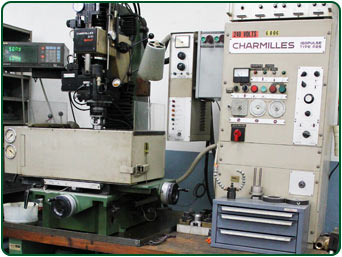

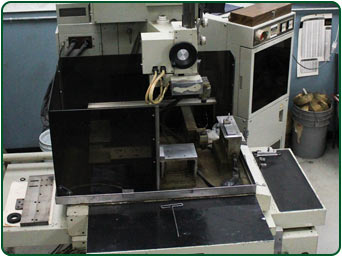

At Peter Paul Electric, Inc. we have been manufacturing coils in Fajardo, Puerto Rico since 1972. Our roots run much deeper through operations that commenced in 1947, through Peter Paul Coil Company, in New Britain, CT. Our years of experience have created expertise in many areas of manufacturing and a mind set to approach any project. We have always been believers that if we can control we should and for this reason you will see throughout this site that we have many capabilities. This expertise begins with our with our tool design, construction and maintenance.

Your parts are only as good as the tools that make them. We maintain our Plastics Molds and Metal Stamping Dies, in house. We are able to offer our customers Coil Winding, Assembly Operations, Metal Stamping and wide array of Plastics Molding Solutions. Our 30 years experience in the Insert and Bobbin Molding arena have created a Molding Team able to serve a wide array of needs. We can serve your thermoset and thermoplastic needs. Our Plastics/Molding services are; Bobbin and High Precision Parts Molding, High Precision Insert Molding.

Our years of experience in the Thermoset type materials created the opportunity for us to make our own molding compounds a facet we believe is an advantage. All of this while maintaining excellence in our Thermoplastic opportunities. The various areas that represent our capabilities should provide our visitors with more information.

Please contact us at info@peterpaulelectric.com